EN-24(SAE 4340)

Alloy steels are designated by AISI four-digit numbers. They comprise different kinds of steels having composition exceeding the limitations of B, C, Mn, Mo, Ni, Si, Cr, and Va set for carbon steels.AISI 4340 alloy steel is a heat treatable and low alloy steel containing chromium, nickel and molybdenum. It has high toughness and strength in the heat treated condition.

| Element | Min | Max |

| C % | 0.36 | 0.44 |

| CR % | 1.00 | 1.40 |

| MN % | 0.45 | 0.70 |

| P % | 0.00 | 0.035 |

| SI % | 0.10 | 0.35 |

| S % | 0.00 | 0.04 |

| Mo % | 0.20 | 0.35 |

| Ni % | 1.30 | 1.70 |

EN-31(SAE 52100)

EN31 is a high carbon Alloy steel which achieves a high degree of hardness with compressive strength and abrasion resistance.Forge at 1000°/1050°C. Heat slowly, allowing sufficient time at the forging temperature for the steel to be thoroughly soaked through. Re-heat as often as necessary to keep the temperature above 850°C. After forging cool very slowly, preferably in a furnace.

| Element | Min | Max |

| C % | 0.90 | 1.20 |

| CR % | 1.00 | 1.60 |

| MN % | 0.30 | 0.75 |

| SI % | 0.10 | 0.35 |

| S % | 0.00 | 0.06 |

| P % | 0.00 | 0.06 |

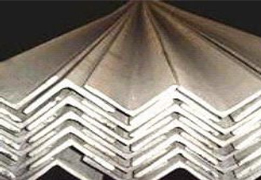

M.S.ANGLE

We also deals in a wide variety of angles of mild steel. These mild steel angles are available in 15mm to 200 mm with standard specifications. Having a cross section of 90-degree angle, these mild steel angles are of structural material. The length and the thickness of the two sides determine dimension of these mild steel angles. Also, these mild steel angles can be made as per the customers requirements. The range of these angles is mild steel channels, mild steel structures and industrial MS angle.

| Element | Min | Max |

| C % | 0.00 | 0.23 |

| Mn % | 0.00 | 1.50 |

| P % | 0.00 | 0.05. |

| S % | 0.00 | 0.05 |

| Si % | 0.00 | 0.40 |

| Cr % | 0.00 | 0.42 |

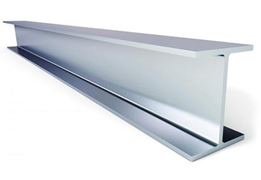

CHENNEL

Steel channel is a hot-rolled carbon steel channel shape. Constructed using a vertical web and top and bottom horizontal flanges with inside radius corners, it is available in a wide range of sizes and thicknesses. The shape provides superior structural support, making it an ideal product for frames and braces used for machinery, enclosure, vehicle, building and structural support applications.

I BEAM

Mild steel I / H beams that we supply and export are extensively used for construction purpose. These superior quality I / H beams are made using high grade raw material and are available in different dimensions. The steel H beams are widely in demand for their durability and industry leading price. All our above mentioned products and there ranges mentioned are standard size, lengths & weights. However we cater to clients who have requirements of specific length, section weight and dimension.

PLATE

We are widely acclaimed for making available high grades of Carbon Steel, which is developed by using premium grade materials. Known for its durability, Carbon Steel is used in the production of an assortment of products. We offer Carbon Steel in various shapes such as round, hex, square, flat, plate, coil and wire sections in standard as well as off sizes. As we supply a wide variety of Carbon Steel it is easier for our clients to select the most efficient and feasible Carbon Steel from the array. Carbon Steel, offered by us, is used in the manufacturing various products. The premium quality of Carbon Steel ensures that the resultant products are too of highest grade.

SAE-1015

Steels with only carbon as their specific alloying element are known as carbon steels. Traces of 0.4% silicon and 1.2% manganese can be found in these steels. Carbon steels also contain small quantities of copper, nickel, molybdenum, aluminium and chromium.

| Element | Min | Max |

| C % | 0.13 | 0.18 |

| MN % | 0.30 | 0.60 |

| S % | 0.00 | 0.05 |

| P % | 0.00 | 0.05 |

SAE-1018

AISI 1018 mild/low carbon steel has excellent weldability and produces a uniform and harder case and it is considered as the best steel for carburized parts. AISI 1018 mild/low carbon steel offers a good balance of toughness, strength and ductility. Provided with higher mechanical properties, AISI 1018 hot rolled steel also includes improved machining characteristics and Brinell hardness.

Specific manufacturing controls are used for surface preparation, chemical composition, rolling and heating processes. All these processes develop a supreme quality product that are suited to fabrication processes such as welding, forging, drilling, machining, cold drawing and heat treating.

| Element | Min | Max |

| C % | 0.15 | 0.2 |

| MN % | 0.60 | 0.90 |

| S % | 0.00 | 0.05 |

| P % | 0.00 | 0.05 |

C-45

MATERIAL SHEETS,STRIP COIL IS AVAILABLE IN CUT TO LENGTH & SLITTING.MATERIAL IS UTILISED SPECIALLY IN CHAIN,SPROKET,WASHERS & OTHER PARTS,ALL THE MATERIAL IS TESTED & IS GIVEN ALONG WITH THE TEST CERTIFICATE.

| Element | Min | Max |

| C % | 0.42 | 0.50 |

| Cr % | 0.20 | 0.40 |

| Si % | 0.15 | 0.35 |

| Mn % | 0.50 | 0.80 |

| P % | 0.00 | 0.025 |

| S % | 0.00 | 0.025 |

C-50

C50 is a medium carbon steel is used when greater strength and hardness is desired than in the as rolled' condition.C50 steel plate, EN 10083 C50 steel plate, under EN 10083 standard, we can regard C50 steel plate as high carbon steel.C50 steel plate is one mainly of high carbon steel,EN 10083 C50 steel plate is one of the higher carbon content (0.47-0.55) steels.

| Element | Min | Max |

| C % | 0.00 | 0.51 |

| Cr % | 0.00 | 0.20 |

| Mo % | 0.00 | 0.05 |

| Mn % | 0.00 | 0.75 |

| Ni % | 0.00 | 0.20 |

| Si % | 0.00 | 0.20 |

C-60

Carbon Steel C 60 Description C 60 steel is one of the higher carbon content (0.60%) steels. It is more difficult to fabricate than the lower carbon grades.

| Element | Min | Max |

| C % | 0.57 | 0.65 |

| Cr % | 0.00 | 0.25 |

| Cu % | 0.00 | 0.30 |

| Mn % | 0.50 | 0.80 |

| Ni % | 0.00 | 0.30 |

| S % | 0.00 | 0.04 |

| Si % | 0.17 | 0.37 |

| P % | 0.00 | 0.35 |

| As % | 0.00 | 0.08 |

40CR 4

EN-1AL

EN1A LEADED 230M07Pb is a low carbon steel designed for high speed machining for multi turned parts. Controlled analysis to ensure consistent quality and maximum tool life. Swarf will form in small chips to prevent machine blockage.The addition of lead will enhance machinability.High machinability, used in automatic and CNC machines for mass production of components like Engine Shafts, Connecting components, Connecting rods, Spindles etc.

| Element | Min | Max |

| C % | 0.00 | 0.15 |

| Mn % | 0.80 | 1.20 |

| Si % | 0.00 | 0.10 |

| S % | 0.25 | 0.35 |

| P % | 0.00 | 0.09 |

EN-8

We are recognized as eminent suppliers and exporters of highly qualitative Carbon Steel EN8. They are fabricated using premium-quality Steel in compliance with industrial norms and guidelines.They are well-known for their high tensile strength. They have a flawless surface finish. Their surface is scratch-resistant and abrasion-proof. These products are dimensionally accurate and are facilitate easy installation and maintenance.We also export these products in a streamlined manner.

| Element | Min | Max |

| C % | 0.35 | 0.45 |

| Mn % | 0.60 | 1.00 |

| P % | 0.00 | 0.06 |

| S % | 0.00 | 0.06 |

| Si % | 0.05 | 0.35 |

| Ni % | 0.00 | 0.00 |

EN-8D

EN8D is a carbon steel, detailed in British Standard BS970 080A42 is a medium carbon and medium tensile steel used mainly for axles, spindles, studs, automotive and general engineering components. Suitable for heat treatment where extra strength is required.

It is medium high carbon steel that can be strengthened by heat treating after forming. Machinability and weldability are fair. Typical uses include machine, plow and carriage bolts, cylinder head studs, machine parts etc. It is also used for U bolts, concrete re-enforcing rods, forgings and non critical springs.

| Element | Min | Max |

| C % | 0.40 | 0.45 |

| Mn % | 0.70 | 0.90 |

| Si % | 0.05 | 0.35 |

| S % | 0.00 | 0.06 |

| P % | 0.00 | 0.06 |

EN-9

We are one of the prominent exporters and suppliers of high-quality Carbon Steel EN9. They are made using premium-quality Stainless Steel at and are highly acclaimed for their unique features like sturdiness and durability. Their resistance to corrosion and abrasion helps them withstand damage with ease. These products are malleable and ductile. They have a flawless surface finish. We supply them to our esteemed clients in customized specifications within the specified time-frame.

| Element | Min | Max |

| C % | 0.50 | 0.60 |

| Mn % | 0.50 | 0.80 |

| Si % | 0.05 | 0.35 |

| S % | 0.00 | 0.06 |

| P % | 0.00 | 0.06 |